Heavy Duty® Hoist Rings

Click part number for CAD model.

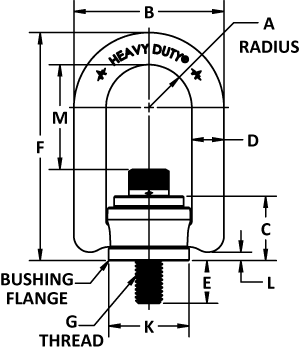

| Part No. |

Rated Load (lbs) |

A | B | C | D | E +/- .12 |

F | G | K | L | M | TL (ft-lbs) |

Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 33112 | 550 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 1/4-20 | 1.25 | 0.15 | 1.57 | 5 | .50 |

| 33212 | 800 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 5/16-18 | 1.25 | 0.15 | 1.51 | 7 | .52 |

| 33213 | 800 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 5/16-24 | 1.25 | 0.15 | 1.51 | 7 | .52 |

| 33214 | 800 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 5/16-18 | 1.25 | 0.15 | 1.51 | 7 | .54 |

| 33312 | 1000 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 3/8-16 | 1.25 | 0.15 | 1.45 | 12 | .56 |

| 33313 | 1000 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 3/8-24 | 1.25 | 0.15 | 1.45 | 12 | .56 |

| 33314 | 1000 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 3/8-16 | 1.25 | 0.15 | 1.45 | 12 | .58 |

| 33316 | 2250 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 1/2-13 | 1.25 | 0.15 | 1.45 | 26 | .60 |

| 33317 | 2250 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 1/2-20 | 1.25 | 0.15 | 1.45 | 26 | .60 |

| 33512 | 2500 | 1.00 | 3.50 | 1.50 | .75 | .75 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.71 |

| •33513 | 2500 | 1.00 | 3.50 | 1.50 | .75 | .75 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.04 |

| 33515 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.72 |

| •33505 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.05 |

| 33516 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.82 |

| •33517 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.15 |

| 33612 | 4000 | 1.00 | 3.50 | 1.50 | .75 | .75 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.76 |

| •33613 | 4000 | 1.00 | 3.50 | 1.50 | .75 | .75 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.09 |

| 33614 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.78 |

| •33604 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.11 |

| 33615 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.88 |

| •33616 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.21 |

| 33714 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 3/4-10 | 1.89 | 0.17 | 2.31 | 100 | 1.89 |

| •33715 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 3/4-10 | 1.89 | 0.17 | 3.87 | 100 | 2.22 |

| 33716 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.50 | 5.31 | 3/4-10 | 1.89 | 0.17 | 2.31 | 100 | 2.02 |

| •33717 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.50 | 6.87 | 3/4-10 | 1.89 | 0.17 | 3.87 | 100 | 2.35 |

| 33110 | 6300 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.23 |

| 33108 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.20 |

| •33168 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.93 |

| 33102 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .1.20 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.23 |

| •33162 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .1.20 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.96 |

| 33103 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.25 |

| •33163 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.98 |

| 33104 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33164 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.95 | 160 | 8.06 |

| 33101 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33161 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.82 | 160 | 8.06 |

| 33109 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33169 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.82 | 160 | 8.06 |

| 33105 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.57 |

| •33165 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.30 |

| 33106 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.63 |

| •33166 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.36 |

| 33107 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 2.20 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.81 |

| •33167 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 2.20 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.54 |

| 33402 | 15000 | 2.00 | 6.75 | 2.89 | 1.25 | 1.88 | 9.22 | 1 1/4″-7 | 3.75 | 0.40 | 3.76 | 470 | 15.7 |

| 33401 | 15000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 1/4″-7 | 3.75 | 0.40 | 3.76 | 470 | 16.0 |

| 33420 | 20000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 3/8″-6 | 3.75 | 0.40 | 3.64 | 670 | 17.2 |

| 33424 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 1/2″-6 | 3.75 | 0.40 | 3.51 | 800 | 18.1 |

| †33436 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.27 | 1 3/4″-5 | 3.75 | 0.40 | 3.51 | 800 | 20.2 |

| †33438 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.27 | 1 3/4″-8 | 3.75 | 0.40 | 3.51 | 800 | 20.2 |

| †33427 | 30000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.22 | 2″-4 1/2 | 3.75 | 0.40 | 3.51 | 1100 | 22.9 |

| †33432 | 30000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.22 | 2″-8 | 3.75 | 0.40 | 3.51 | 1100 | 22.9 |

| New Items | |||||||||||||

| 33501 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2 1/2″-8 | 5.16 | 0.58 | 4.9 | 2400 | 50.4 |

| 33503 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2 1/2″-4 | 5.16 | 0.58 | 4.9 | 2400 | 50.4 |

| 33590 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2 1/2″-8 | 5.16 | 0.58 | 4.47 | 56 | 57.2 |

| 33592 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2 1/2″-4 | 5.16 | 0.58 | 4.47 | 56 | 57.2 |

* Recommended Torque Load

• Long Bar Models

† Supplied with stud and nut

^ The 7,000 lb. W.L.L. when loaded at 90 degrees to the bolt axis, is established with a 4.5 design factor

For Load ranges up to 250,000 lbs. Refer to Our Safety Engineered Hoist Rings

Heavy Duty® Hoist Rings are completely interchangeable with Safety Engineered Hoist Rings or Easy Torque® Hoist Rings.

Heavy Duty® Hoist Rings - Metric

Click part number for CAD model.

| Part No. |

Rated Load (kg) |

A | B | C | D | E +/- 3.0 |

F | G | K | L | M | TL (Nm) |

Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 34212 | 400 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82.0 | M8x1.25 | 31.8 | 4.0 | 38.5 | 9 | .24 |

| 34214 | 400 | 16.5 | 58.2 | 24.4 | 11.1 | 21 | 82.0 | M8x1.25 | 31.8 | 4.0 | 38.5 | 9 | .25 |

| 34312 | 450 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82.0 | M10x1.5 | 31.8 | 4.0 | 36.5 | 16 | .25 |

| 34314 | 450 | 16.5 | 58.2 | 24.4 | 11.1 | 26 | 82.0 | M10x1.5 | 31.8 | 4.0 | 36.5 | 16 | .26 |

| 34515 | 1050 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M12x1.75 | 48.0 | 4.4 | 65.0 | 37 | .78 |

| •34505 | 1050 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 174.6 | M12x1.75 | 48.0 | 4.4 | 104.7 | 37 | .93 |

| 34516 | 1050 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 134.9 | M12x1.75 | 48.0 | 4.4 | 65.0 | 37 | .83 |

| •34517 | 1050 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 174.6 | M12x1.75 | 48.0 | 4.4 | 101.7 | 37 | .98 |

| 34518 | 1500 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 135.2 | M14x2.0 | 48 | 4.4 | 65.3 | 45 | .79 |

| •34519 | 1500 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 174.9 | M14x2.0 | 48 | 4.4 | 105 | 45 | .95 |

| 34520 | 1500 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 135.2 | M14x2.0 | 48 | 4.4 | 65.3 | 45 | .84 |

| •34521 | 1500 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 174.9 | M14x2.0 | 48 | 4.4 | 105 | 45 | .98 |

| 34614 | 1900 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M16x2.0 | 48.0 | 4.4 | 62.0 | 80 | .81 |

| •34604 | 1900 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 174.6 | M16x2.0 | 48.0 | 4.4 | 101.7 | 80 | .96 |

| 34615 | 1900 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 134.9 | M16x2.0 | 48.0 | 4.4 | 62.0 | 80 | .85 |

| •34616 | 1900 | 25.4 | 88.9 | 38.1 | 19.1 | 32 | 174.6 | M16x2.0 | 48.0 | 4.4 | 101.7 | 80 | 1.00 |

| 34714 | 2200 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.6 | M20x2.5 | 48.0 | 4.4 | 58.7 | 135 | .86 |

| •34715 | 2200 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 174.6 | M20x2.5 | 48.0 | 4.4 | 98.4 | 135 | 1.01 |

| 34716 | 2200 | 25.4 | 88.9 | 38.1 | 19.1 | 38 | 134.6 | M20x2.5 | 48.0 | 4.4 | 58.7 | 135 | .92 |

| •34717 | 2200 | 25.4 | 88.9 | 38.1 | 19.1 | 38 | 174.6 | M20x2.5 | 48.0 | 4.4 | 98.4 | 135 | 1.07 |

| 34101 | 3000 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 187.2 | M20x2.5 | 71.4 | 4.6 | 89.7 | 135 | 3.14 |

| •34161 | 3000 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 228.6 | M20x2.5 | 71.4 | 4.6 | 131.1 | 135 | 3.47 |

| 34102 | 4200 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 187.2 | M24x3.0 | 71.4 | 4.6 | 85.7 | 310 | 3.29 |

| •34162 | 4200 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 228.6 | M24x3.0 | 71.4 | 4.6 | 127.1 | 310 | 3.62 |

| 34103 | 4200 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 187.2 | M24x3.0 | 71.4 | 4.6 | 85.7 | 310 | 3.30 |

| •34163 | 4200 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 228.6 | M24x3.0 | 71.4 | 4.6 | 127.1 | 310 | 3.63 |

| 34105 | 4500 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 187.2 | M30x3.5 | 71.4 | 4.6 | 79.7 | 310 | 3.44 |

| •34165 | 4500 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 228.6 | M30x3.5 | 71.4 | 4.6 | 79.7 | 310 | 3.55 |

| 34107 | 4500 | 35.6 | 129.5 | 52.1 | 25.4 | 48 | 187.2 | M30x3.5 | 71.4 | 4.6 | 79.7 | 310 | 3.55 |

| •34167 | 4500 | 35.6 | 129.5 | 52.1 | 25.4 | 48 | 228.6 | M30x3.5 | 71.4 | 4.6 | 121.1 | 310 | 3.88 |

| 34401 | 7000 | 50.8 | 171.5 | 72.9 | 31.8 | 67 | 234.2 | M30x3.5 | 98.5 | 8.2 | 95.0 | 635 | 7.26 |

| 34402 | 11000 | 50.8 | 171.5 | 72.9 | 31.8 | 67 | 234.2 | M36x4.0 | 98.5 | 8.2 | 88.6 | 1085 | 8.21 |

| †34403 | 12500 | 50.8 | 171.5 | 72.9 | 31.8 | 80 | 234.2 | M42x4.5 | 98.5 | 8.2 | 88.6 | 1085 | 10.14 |

| †34404 | 13500 | 50.8 | 171.5 | 72.9 | 31.8 | 80 | 234.2 | M48x5.0 | 98.5 | 8.2 | 88.6 | 1085 | 10.59 |

| †34406 | 13500 | 50.8 | 171.5 | 72.9 | 31.8 | 88 | 234.2 | M56x5.5 | 98.5 | 8.2 | 88.6 | 1085 | 11.03 |

| New Items | |||||||||||||

| 34060 | 25000 | 69.9 | 235 | 100.6 | 44.5 | 102 | 326.6 | M64-6.0 | 131.1 | 14.7 | 124.5 | 3600 | 25.9 |

| 34592 | 25000 | 69.9 | 235 | 100.6 | 44.5 | 102 | 326.6 | M64 x 6.0 | 131.1 | 14.7 | 124.5 | 76 | 25.9 |

* Recommended Torque Load

• Long Bar Models

† Supplied with stud and nut

Note: Dimensions are in millimeters

For Load Ranges up to 113,400 KG. Refer to Our safety Engineered Hoist Rings.

Heavy Duty® Hoist Rings are completely interchangeable with Safety Engineered Hoist Rings.

Material: Forged and machined high strength alloy steel

Design Factor: Minimum Design Factor = 5:1, Magnetic Particle Inspected Per ASTM E1444, Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis

Range of Movement: Swivel 360°, Pivot 180° Under Load

Specifications: Meets Military Specification No. MIL-STD 209, Meets ANSI/ASME B30.26

Finish: Black Oxide Finish for corrosion resistance, * Also available in a wide range of plating – e.g Cadmium, Titanium-Cadmium, Nickel, etc.

range of plating – e.g Cadmium, Titanium-Cadmium, Nickel, etc.

Typical Applications: ADB’s Heavy Duty® Hoist Rings are specified and used in nuclear energy equipment

200% Proof Load Tested

Individually Serial Numbered

All dimensions approximate variations do not effect use or design factor.