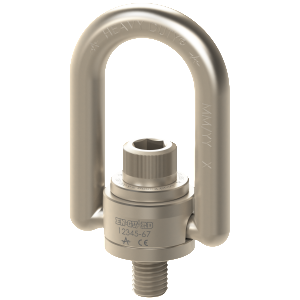

- Forged High Strength 4140 Alloy Steel Hoist Ring

- Corrosion Resistant Plating – Electroless Nickel (AMS-C-26074 Class 1 Grade B)

- 200% Proof Load Tested

- Individually Serialized

- Other Standard and Metric Sizes Available

- Select Sizes from 550-30,000 lbs

- Swivels 360°, Pivots 180°

- Easily disassembled & reassembled for inspection

- Compiles with ASME-B30.26

- 5:1 Design Factor

- Unlike eye bolts, swivel hoist rings maintain full capacity at 0-90 degrees from the bolt axis.

Click part number for CAD model.

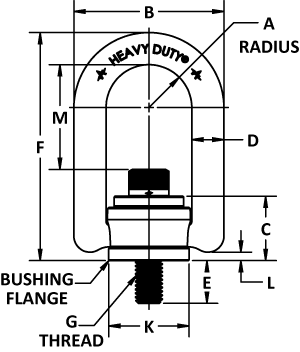

| Inch | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (lbs) |

A | B | C | D | E +/- .12 |

F | G | K | L | M | TL* (ft-lbs) |

Weight (lbs) |

| EN33112 | 550 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 1/4-20 | 1.25 | 0.15 | 1.57 | 5 | 0.50 |

| EN33212 | 800 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 5/16-18 | 1.25 | 0.15 | 1.51 | 7 | 0.52 |

| EN33312 | 1000 | 0.65 | 2.29 | 0.96 | 0.44 | 0.56 | 3.23 | 3/8-16 | 1.25 | 0.15 | 1.45 | 12 | 0.56 |

| EN33512 | 2500 | 1 | 3.5 | 1.5 | 0.75 | 0.75 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.71 |

| EN33614 | 4000 | 1 | 3.5 | 1.5 | 0.75 | 1 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.78 |

| EN33714 | 5000 | 1 | 3.5 | 1.5 | 0.75 | 1 | 5.31 | 3/4-10 | 1.89 | 0.17 | 2.31 | 100 | 1.89 |

| EN33102 | 7000^ | 1.5 | 5.1 | 2.05 | 1 | 1.20 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.23 |

| EN33104 | 8000 | 1.5 | 5.1 | 2.05 | 1 | 0.95 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| EN33105 | 10000 | 1.5 | 5.1 | 2.05 | 1 | 1.45 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.2 | 230 | 7.57 |

| EN33402 | 15000 | 2 | 6.75 | 2.87 | 1.25 | 1.88 | 9.22 | 1 1/4″-7 | 3.88 | 0.18 | 3.74 | 470 | 15.74 |

| EN33424 | 24000 | 2 | 6.75 | 2.87 | 1.25 | 2.63 | 9.22 | 1 1/2″-6 | 3.88 | 0.32 | 3.49 | 800 | 18.1 |

| †EN33427 | 30000 | 2 | 6.75 | 2.87 | 1.25 | 2.96 | 9.22 | 2″-4 1/2 | 3.88 | 0.32 | 3.49 | 1100 | 22.9 |

| Metric | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (kg) |

A | B | C | D | E +/- 3.0 |

F | G | K | L | M | TL* (Nm) |

Weight (kg) |

| EN34212 | 400 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82 | M8 x 125 | 31.8 | 4 | 38.5 | 9 | 0.24 |

| EN34312 | 450 | 16.5 | 58.2 | 24.4 | 11.1 | 16 | 82 | M10 x 1.5 | 31.8 | 4 | 36.5 | 16 | 0.25 |

| EN34515 | 1050 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M12 x 1.75 | 48 | 4.4 | 65 | 37 | 0.78 |

| EN34518 | 1500 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 135.2 | M14 x 2.0 | 48 | 4.4 | 65.3 | 45 | 0.79 |

| EN34614 | 1900 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.9 | M16 x 2.0 | 48 | 4.4 | 62 | 80 | 0.81 |

| EN34714 | 2200 | 25.4 | 88.9 | 38.1 | 19.1 | 25 | 134.6 | M20 x 2.5 | 48 | 4.4 | 58.7 | 135 | 0.86 |

| EN34102 | 4200 | 35.6 | 129.5 | 52.1 | 25.4 | 28 | 187.2 | M24 x 3.0 | 71.4 | 4.6 | 85.7 | 310 | 3.29 |

| EN34105 | 4500 | 35.6 | 129.5 | 52.1 | 25.4 | 38 | 187.2 | M30 x 3.5 | 71.4 | 4.6 | 79.7 | 310 | 3.44 |

* Recommended Torque Load

** Plating threads may subject threads to not meet standard thread tolerances

† Supplied with stud and nut

^ The 7,000 lb. W.L.L. when loaded at 90 degrees to the bolt axis, is established with a 4.5 design factor