Material: High strength 4140 alloy steel

Material: High strength 4140 alloy steel

Design Factor: 5:1, Magnetic Particle Inspected Per ASTM E1444. Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis.

Range of Movement: Swivel 360°, Pivot 180° Under Load

Finish: Black Oxide finish for corrosion resistance*

Typical Applications: ADB, the originator and leader in safety hoist rings, introduces another time and money saving innovation. ADB’s new EZ-Torq ue® Hoist Ring eliminates the need of locating and installing hydraulic torque multipliers for large hoist ring installations. A 75,000 lb. rated load hoist ring requires the mounting screw to be torqued to 4,300 ft.lbs. Using ADB’s EZ-Torque® Hoist Ring requires only a standard torque wrench and 92 ft.lbs. of torque per bolt!

ue® Hoist Ring eliminates the need of locating and installing hydraulic torque multipliers for large hoist ring installations. A 75,000 lb. rated load hoist ring requires the mounting screw to be torqued to 4,300 ft.lbs. Using ADB’s EZ-Torque® Hoist Ring requires only a standard torque wrench and 92 ft.lbs. of torque per bolt!

Patent Numbers: 5,848,815

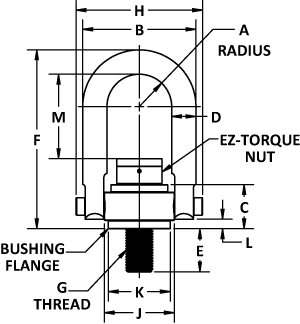

All dimensions approximate – variations do not effect use or design factor.

* Also available in a wide range of plating – e.g Cadmium, Titanium-Cadmium, Nickel, etc.

Click part number for CAD model.

| EZ-Torque® Hoist Rings | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (lbs) |

A | B | C | D | E +/- .12 |

F | G | H | J | K | L | M | TL (ft-lbs) |

EZ-Torque (ft-lbs) |

Weight (lbs) |

| 23490 | 15000 | 1.75 | 6.0 | 2.11 | 1 1/4 | 1.89 | 8.73 | 1 1/4″-7 | 6.50 | 3.76 | 3.20 | 0.35 | 3.88 | 470 | 10 | 16.00 |

| 23494 | 24000 | 2.25 | 8.0 | 2.81 | 1 3/4 | 2.70 | 12.47 | 1 1/2″-6 | 8.55 | 4.87 | 4.20 | 0.47 | 6.12 | 800 | 18 | 37.75 |

| 23290 | 30000 | 2.25 | 8.0 | 2.81 | 1 3/4 | 2.96 | 12.47 | 2″-4 1/2 | 8.55 | 4.87 | 4.20 | 0.47 | 6.12 | 1100 | 23 | 39.00 |

| †23590 | 50000 | 3.00 | 10.5 | 4.09 | 2 1/4 | 4.00 | 16.87 | 2 1/2″-8 | 11.67 | 6.52 | 5.75 | 1.12 | 7.73 | 2100 | 49 | 92.00 |

| †23592 | 50000 | 3.00 | 10.5 | 4.09 | 2 1/4 | 4.00 | 16.87 | 2 1/2″-4 | 11.67 | 6.52 | 5.75 | 1.12 | 7.73 | 2100 | 49 | 92.00 |

| †23690 | 75000 | 3.75 | 13.0 | 5.27 | 2 3/4 | 5.20 | 19.50 | 3″-4 | 14.15 | 8.10 | 7.25 | 1.00 | 8.53 | 4300 | 92 | 174.60 |

| 23790 | 100,000 | 4.00 | 14.5 | 6.06 | 3 1/4 | 7.00 | 22.09 | 3 1/2″-4 | 15.90 | 8.60 | 7.75 | 1.09 | 9.28 | 6600 | 98 | 246.94 |

| 23792 | 150,000 | 5.00 | 18.0 | 7.50 | 4 | 8.50 | 27.38 | 4 1/4″-4 | 19.69 | 10.75 | 9.87 | 1.33 | 12.93 | 12000 | 123 | 527.00 |

| 23794 | 200,000 | 6.00 | 22.0 | 9.00 | 5 | 9.00 | 33.00 | 5″-4 | 24.00 | 13.00 | 12.38 | 1.88 | 15.00 | 19800 | 193 | 763.00 |

| 23798 | 250,000 | 6.00 | 22.0 | 9.00 | 5 | 9.00 | 33.00 | 6″-4 | 24.00 | 13.00 | 12.38 | 1.88 | 15.00 | 29000 | 207 | 841.00 |

| EZ-Torque® Hoist Rings – Metric | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (kg) |

A | B | C | D | E +/- 3.0 |

F | G | H | J | K | L | M | TL (Nm) |

EZ-Torque (Nm) |

Weight (kg) |

| 24490 | 7000 | 44.5 | 152.4 | 53.6 | 31.8 | 66 | 221.7 | M30 x 3.5 | 165.1 | 95.5 | 81.3 | 8.9 | 106.3 | 635 | 13.5 | 7.26 |

| 24494 | 11000 | 57.2 | 203.2 | 71.4 | 44.5 | 69 | 316.7 | M36 x 4.0 | 217.2 | 123.7 | 106.7 | 11.9 | 164.8 | 1085 | 21 | 17.13 |

| 24498 | 12500 | 57.2 | 203.2 | 71.4 | 44.5 | 79 | 316.7 | M42 x 4.5 | 217.2 | 123.7 | 106.7 | 11.9 | 158.8 | 1085 | 22 | 17.13 |

| 24290 | 13500 | 57.2 | 203.2 | 71.4 | 44.5 | 79 | 316.7 | M48 x 5.0 | 217.2 | 123.7 | 106.7 | 11.9 | 152.8 | 1085 | 22 | 17.69 |

| †24592 | 22000 | 76.2 | 266.7 | 104.0 | 57.2 | 102 | 428.5 | M64 x 6.0 | 296.4 | 165.6 | 146.1 | 28.4 | 203.3 | 2845 | 54 | 41.73 |

| †24690 | 31500 | 95.2 | 330.2 | 133.9 | 69.8 | 132 | 495.3 | M72 x 6.0 | 368.3 | 205.7 | 184.1 | 25.4 | 215.4 | 5670 | 125 | 79.20 |

| 24790 | 51000 | 101.6 | 368.3 | 153.9 | 82.5 | 178 | 561.1 | M90 x 6.0 | 403.9 | 218.4 | 196.8 | 27.7 | 235.7 | 9560 | 133 | 112.01 |

† Exception to standard discounts

*Recommended Torque Load per each installation bolt

Larger WLL available upon request