The H.E. 360™ is a revolutionary engineered lifting point which meets the performance requirements and compliance with modern rigging hardware standards such as ASME B30.26. With each being proof tested to 200% of the marked working load limit, the H.E. 360™ can provide additional assurances related to safe lifting. The design has a 5:1 factor in all angular directions and maintains the same working load limit without a reduction of tool working load limit like common eyebolts. The H.E. 360™ is easily installed with common size ball end stubby allen wrenches and in cases of having to comply with the marked recommended permanent installation torque (PITQ), an offset tool is available from ADB.

- Design allows for eye rotation prior to lifting or load handling activities.

- Effective thread length 1 1/2 times the diameter

- WLL and Torque recommendation properly marked.

- Angular loading permissible without reduction of WLL when shoulder is flush to surface.

- Distinctive Green Powder Coated Body

- Corrosion Resistant Plated Body, Fastener, Bushing and Retaining Ring

- Replaceable Mounting Screw

- Special Configurations Available Upon Request

- 200% Proof Load Tested

- Made in USA

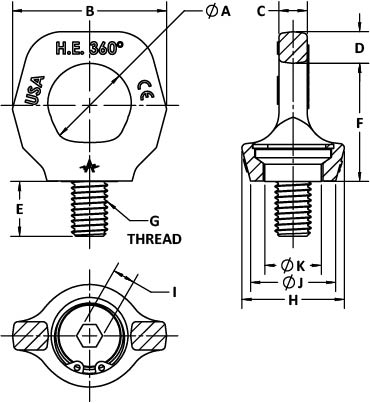

All dimensions approximate – variations do not effect use or design factor.

Click on part number to see CAD model.

| Hoist Eye 360® | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (lbs) | Torque (ft-lbs) | A | B | C | D | E | F | G | H | I | J | K | Hex Key | Weight (lbs) | Offset Hex Key | ||

| 71120 | 880 | 12 | 0.96 | 1.81 | 0.36 | 0.37 | 0.61 | 1.40 | 3/8-16 | 1.19 | 7/32 | 1.00 | 0.59 | 72006 | 0.26 | 71129 | ||

| 71146 | 1650 | 28 | 1.16 | 2.14 | 0.39 | 0.44 | 0.76 | 1.64 | 1/2-13 | 1.42 | 5/16 | 1.18 | 0.79 | 72008 | 0.42 | 71156 | ||

| 71160 | 3000 | 47 | 1.30 | 2.55 | 0.55 | 0.50 | 0.94 | 1.94 | 5/8-11 | 1.69 | 3/8 | 1.38 | 0.94 | 72009 | 0.79 | 71170 | ||

| 71174 | 4500 | 84 | 1.50 | 2.95 | 0.63 | 0.59 | 1.18 | 2.30 | 3/4-10 | 2.00 | 1/2 | 1.65 | 1.14 | 72011 | 1.26 | 71184 | ||

| 71198 | 7050 | 230 | 1.84 | 3.53 | 0.75 | 0.72 | 1.50 | 2.82 | 1-8 | 2.35 | 5/8 | 1.97 | 1.34 | 72013 | 2.20 | 71208 | ||

| Hoist Eye 360® – Metric | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Rated Load (kg) | Torque (Nm) | A | B | C | D | E | F | G | H | I | J | K | Hex Key | Weight (kg) | Offset Hex Key | ||

| 71420 | 0,4t | 16 | 24 | 46 | 9 | 9 | 15 | 36 | M10 x 1.5 | 30 | 6 | 25.4 | 15.0 | 72006 | 0.12 | 71429 | ||

| 71446 | 0,75t | 38 | 29 | 54 | 10 | 11 | 19 | 42 | M12 x 1.75 | 36 | 8 | 30.0 | 20.0 | 72008 | 0.19 | 71456 | ||

| 71460 | 1,4t | 64 | 33 | 65 | 14 | 13 | 24 | 49 | M16 x 2.0 | 43 | 10 | 35.0 | 23.7 | 72009 | 0.36 | 71470 | ||

| 71474 | 2,0t | 114 | 38 | 75 | 16 | 15 | 30 | 58 | M20 x 2.5 | 51 | 12 | 42.0 | 29.0 | 72011 | 0.57 | 71484 | ||

| 71498 | 2,7t | 195 | 47 | 90 | 19 | 18 | 38 | 72 | M24 x 3.0 | 60 | 14 | 50.0 | 34.0 | 72013 | 1.00 | 71508 | ||

| 71512 | 3,2t | 313 | 46.7 | 89.7 | 19.1 | 18.13 | 45 | 71.6 | M30 x 3.5 | 60 | 17 | 50.0 | 34.0 | 72040 | 1.00 | 71519 | ||

* Note: Rated load is based on 180,000 psi ultimate tensile strength of bolt or stud. If a bolt with lower strength is used or workpiece anchor material is incapable of supporting this weight, the applied load must be reduced accordingly.

** Plating threads may subject threads to not meet standard thread tolerances